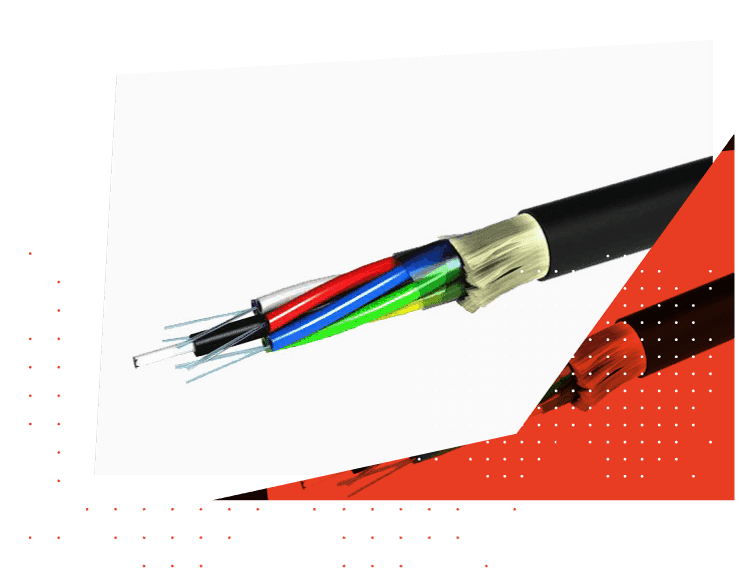

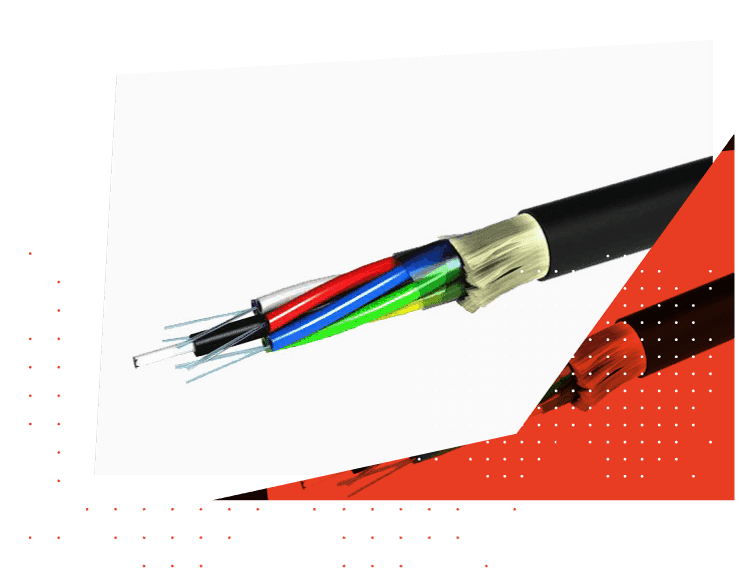

Fiber-optic cables are joined or “spliced” together, mainly to satisfy the length requirement of a particular installation. Most cable manufacturers offer very limited lengths of fiber-optic cables, around 1 to 6 kilometers. If an installation requires more than the length of any available cables, there’s no need to call in for a special order, two cables can simply be spliced from end to end. Splicing is also applicable when your existing cables are inadvertently severed; splicing is a way to restore the fiber-optic cables without replacing the entire installation.

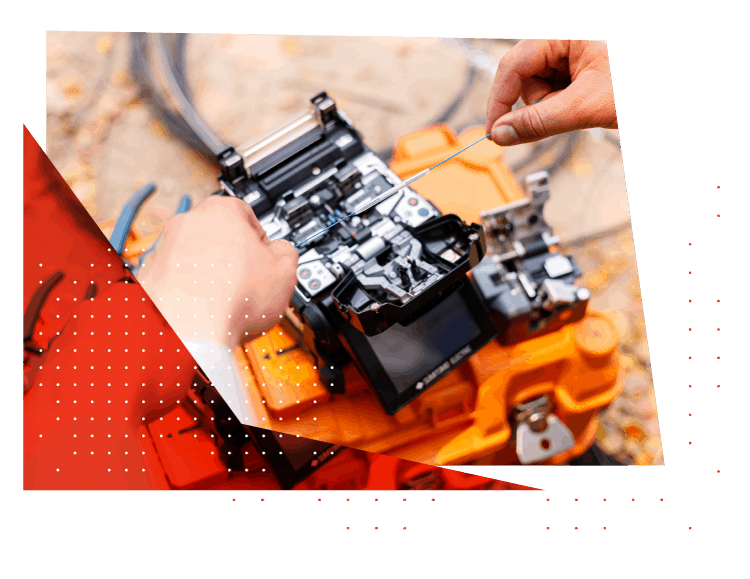

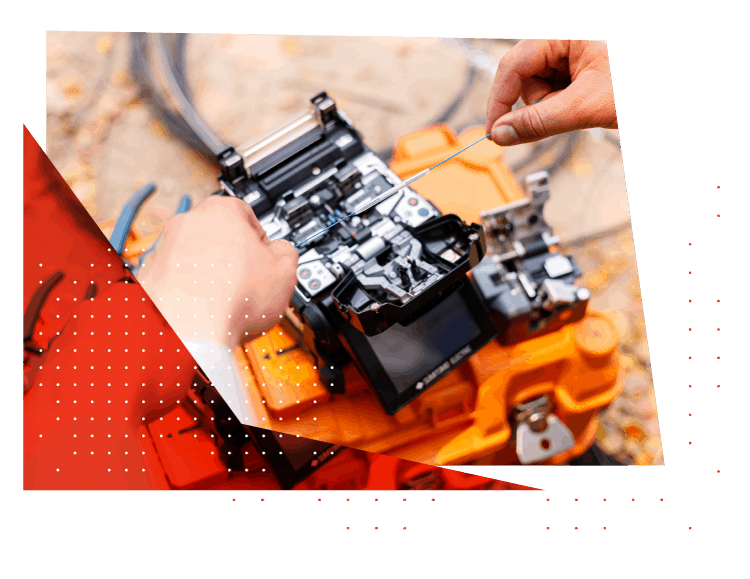

Fusion Splicer for Fiber Optic Cabling

The idea may be a simple one, but the actual splicing process is very technical and requires special skill sets and tools. It takes precision because all light should pass from one cable to another with very minimal, if not none at all, amount of scattering for maximum efficiency.

The two most common methods of splicing are mechanical splicing and fusion splicing. ACIS® IT Solutions employs both methods to the highest standards, ensuring that all your fiber-optic needs are met.

What is Fusion Splicing?

In fusion splicing, two fiber optic cables are joined from end to end with the use of heat. Whether if it’s for a new installation or a restoration, the main goal is to not let any light be dispersed or reflected by the junction where the two ends are to meet. At the end of splicing, the product should be close to that of a new and uncut fiber-optic cable. It employs a variety of heat sources; the most commonly used is an electric arc, although gas flames, tungsten filaments, or lasers are also used. Because the two ends are pretty much joined as one, there will be very minimal loss of light, enhancing the cable’s performance.

What’s the difference between Fusion Splicing and Mechanical Splicing?

While Fusion Splicing uses heat to merge the ends of two cables, Mechanical Splicing joins two or more cables with a mechanical fixture or apparatus. The ends are aligned precisely before the apparatus is applied to hold the two ends in place. A special gel is sometimes used to diminish the amount of reflection of light, although there is still a small amount of light lost after splicing, around 0.3 dB (Optical Loss is measured in dB).

Because the ends of two cables are fused together seamlessly in Fusion Splicing, there is less reflection and thus, the performance is enhanced. Fusion splicing is more often used with single mode optical fibers (SMF). There are still many companies that use multi-mode fibers, and Mechanical Splicing can be used for these companies. Mechanical Splicing is more flexible in terms of usage, it can be used both for single and multi-mode fibers. It is used by many companies for their local, short cables.

Nowadays, companies are leaning towards using single mode fibers in the future. In that case, Fusion Splicing will be more beneficial for these companies. But of course, replacing a company’s installation is a long and tedious process, so it may take a while. Until the time comes that everyone’s using single mode fibers, Mechanical Splicing will remain the only method for companies who uses multi-mode fiber.

What processes are involved in Fusion Splicing?

ACIS® IT Solutions uses the Greenlee 910FS Fusion Splicer and Cleaver, which is one of the best available Fusion Splicing kits in the market today. Everything is automated, and this kit is fitted with a 5.7” color LCD that displays images from dual cameras at 240x magnification. Our team of highly-skilled and certified fiber optics technicians uses this kit to analyze cleaved ends faster, and create clean and durable connection each and every time. Fusion kits are just tools, but it is the technician’s steady hands that make our works impeccable.

Contact us so we can start to help you get the most out of installations. Whether it’s for designing or installation, our team of experts will surely deliver the utmost service and best results.

Stripping the Ends of the Fibers – The optical fiber is covered by a protective layer of polymer. This layer is removed from both ends of the cables to be joined prior to splicing.

Cleaning and Cleaving the ends – After stripping the ends, they are cleaned with a solution to remove any impurities or debris from stripping that may affect future performance. Cleaving is flattening the endface that it is at a 90-degree angle with the fiber. Optical loss is lessened if the angle is close to 90-degrees.

Splicing the ends – The two ends are aligned perfectly and automatically by the fusion splicer prior to fusion. Tests are also done to ensure that the junction can withstand transport, packaging, and usage. The newly spliced area is protected with either a splice protector, or by recoating.

ACIS® IT Solutions uses the Greenlee 910FS Fusion Splicer and Cleaver, which is one of the best available Fusion Splicing kits in the market today. Everything is automated, and this kit is fitted with a 5.7” color LCD that displays images from dual cameras at 240x magnification. Our team of highly-skilled and certified fiber optics technicians uses this kit to analyze cleaved ends faster, and create clean and durable connection each and every time. Fusion kits are just tools, but it is the technician’s steady hands that make our works impeccable.

Contact us so we can start to help you get the most out of installations. Whether it’s for designing or installation, our team of experts will surely deliver the utmost service and best results.

“ACIS® computers is a great company to have service all your networking, computer and IT needs. They have the knowledge and skills to come up with solutions for complex IT situations.”

Dale Replogle